As an accomplished designer, I have acquired the skills necessary to bring a product to life. From concept to manufacturing and on to final product.

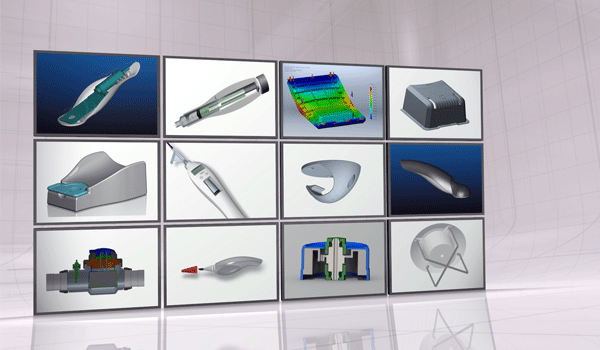

Here are some images of products I prototyped and modelled in CAD for production during my time at Design Momentum in Sydney, Australia. Please refer to the "Case Studies" section of this site for a closer look at some of the challenges overcome in the featured products.

During my time with Product Design Consultancies, I gained experience across multiple industries gaining experience in the medical device and consumer product catergories.